Superior Tooling now part of SHL Advantec

SHL Medical, a world leader in self-injection solutions, today announced plans to establish SHL Advantec – a dynamic sub-group dedicated to providing tooling and automation solutions to the healthcare sector and other industries.

Together with SHL Medical’s recent strategic acquisitions – Swiss-based LCA Automation and SMC Mould Innovation and US-based Superior Tooling – SHL Advantec will form a global operations network spanning three continents to deliver faster support and shorter supply chain services to SHL Advantec’s diverse customer base.

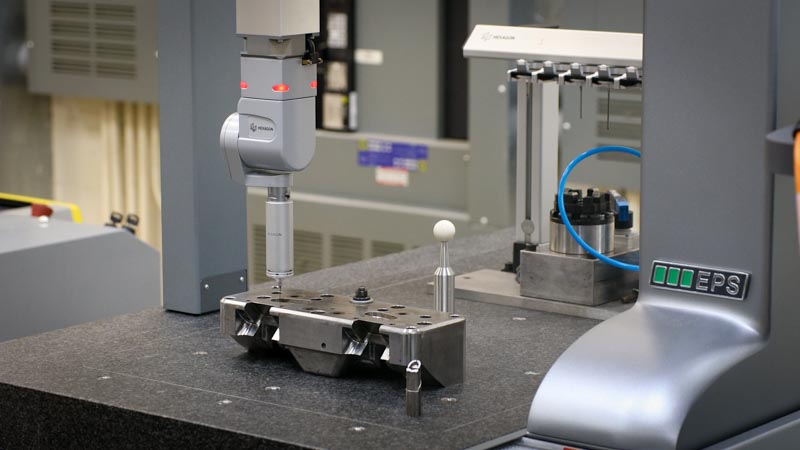

More Measuring

We are proud to introduce you to our newest Coordinate Measuring Machine (CMM). We have dramatically improved our capacity with a new Hexagon Global S CMM with 5-axis probe, automatic stylus changer, and continuous path scanning capabilities. This powerful machine expands our capabilities for part and tool inspection, as well as reverse engineering.

We are proud to introduce you to our newest Coordinate Measuring Machine (CMM). We have dramatically improved our capacity with a new Hexagon Global S CMM with 5-axis probe, automatic stylus changer, and continuous path scanning capabilities. This powerful machine expands our capabilities for part and tool inspection, as well as reverse engineering.

Okuma Turn Mill

The recent addition of our new Okuma LB3000 EX II turning center adds exciting one and done capability for many of our round turned and milled parts. Live tooling combined with automatic tool and part probing means many parts can be turned and milled in one setup for higher productivity with improved accuracy.

The recent addition of our new Okuma LB3000 EX II turning center adds exciting one and done capability for many of our round turned and milled parts. Live tooling combined with automatic tool and part probing means many parts can be turned and milled in one setup for higher productivity with improved accuracy.

5-Axis High Speed Mill

We recently added to our 5-axis contour milling capability with a new Mikron Mill S 400 U machine. This impressive machine includes laser tool probing, automatic part probing, and is fully integrated with our System 3R Workmaster robot to enhance our productivity with 24/7 unattended capability.

We recently added to our 5-axis contour milling capability with a new Mikron Mill S 400 U machine. This impressive machine includes laser tool probing, automatic part probing, and is fully integrated with our System 3R Workmaster robot to enhance our productivity with 24/7 unattended capability.

Horizontal Machining Center

We recently added heavy-duty machining capability with a new Makino a61nx Horizontal Machining Center. Equipped with a 2-station automatic pallet changer, 4-axis contouring, and 4-sided tombstones, this machine is equipped for high productivity at impressive close tolerances.

We recently added heavy-duty machining capability with a new Makino a61nx Horizontal Machining Center. Equipped with a 2-station automatic pallet changer, 4-axis contouring, and 4-sided tombstones, this machine is equipped for high productivity at impressive close tolerances.

NCTAP Apprenticeship Program

Superior Tooling is working with the State of North Carolina to help develop the workforce of the future. NCTAP employers pay apprentices a good salary as they build technical skills, combined with a job-focused technical college.

Superior Tooling is working with the State of North Carolina to help develop the workforce of the future. NCTAP employers pay apprentices a good salary as they build technical skills, combined with a job-focused technical college.

Superior Tooling Tech Center

Within our Superior Tooling facility is a tech center providing our clients with a variety of presses and a private work area for project development. Your team can work with our mold and tooling experts in a private, climate-controlled space to optimize your product and productivity.

Within our Superior Tooling facility is a tech center providing our clients with a variety of presses and a private work area for project development. Your team can work with our mold and tooling experts in a private, climate-controlled space to optimize your product and productivity.

Molding Presses

We offer in-house process development, mold trial and validation, as well as prototype and early part production. Equipped with 3 molding presses to 320 Ton, and a broad selection of support equipment like dryers, chillers, Thermolator temperature control units, sprue pickers, and more, we can run most of the plastic injection molds we build.

We offer in-house process development, mold trial and validation, as well as prototype and early part production. Equipped with 3 molding presses to 320 Ton, and a broad selection of support equipment like dryers, chillers, Thermolator temperature control units, sprue pickers, and more, we can run most of the plastic injection molds we build.

Cylindrical Grinder

The Studer "Favorite CNC" cylindrical grinder is an ultra-precision piece of equipment known for holding consistent tolerances to millionths of an inch. Equipment like this helps us excel in high quality molds for demanding applications like medical and aerospace.

The Studer "Favorite CNC" cylindrical grinder is an ultra-precision piece of equipment known for holding consistent tolerances to millionths of an inch. Equipment like this helps us excel in high quality molds for demanding applications like medical and aerospace.

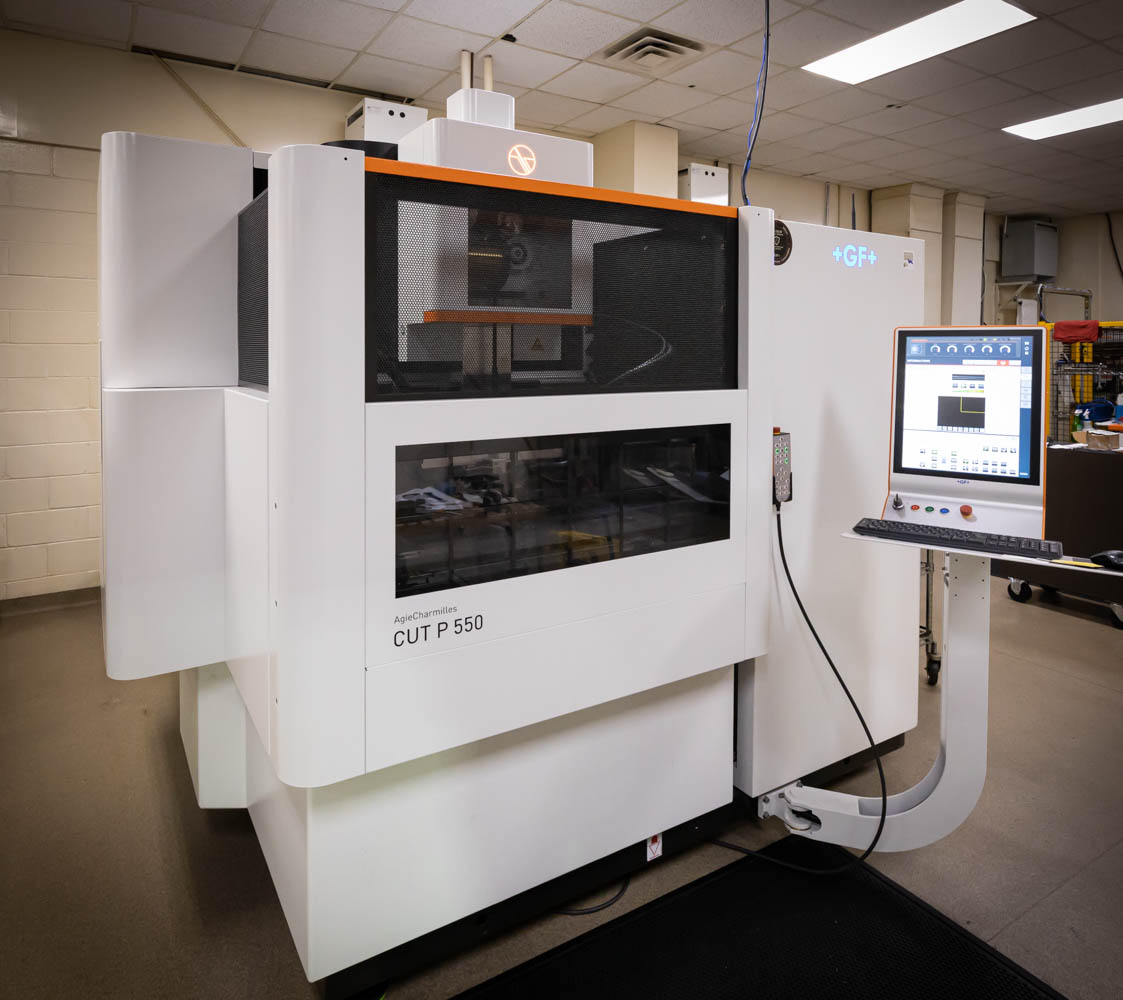

Wire EDM

Our New Agie Charmilles CUT P 550 Wire EDM machine takes our capability to a new level, featuring a 20% reduction in cut times while actually improving accuracy and reducing environmental impacts. This amazing machine can use wire as fine as 0.004" diameter for minute details!

Our New Agie Charmilles CUT P 550 Wire EDM machine takes our capability to a new level, featuring a 20% reduction in cut times while actually improving accuracy and reducing environmental impacts. This amazing machine can use wire as fine as 0.004" diameter for minute details!

New CNC Turning Center

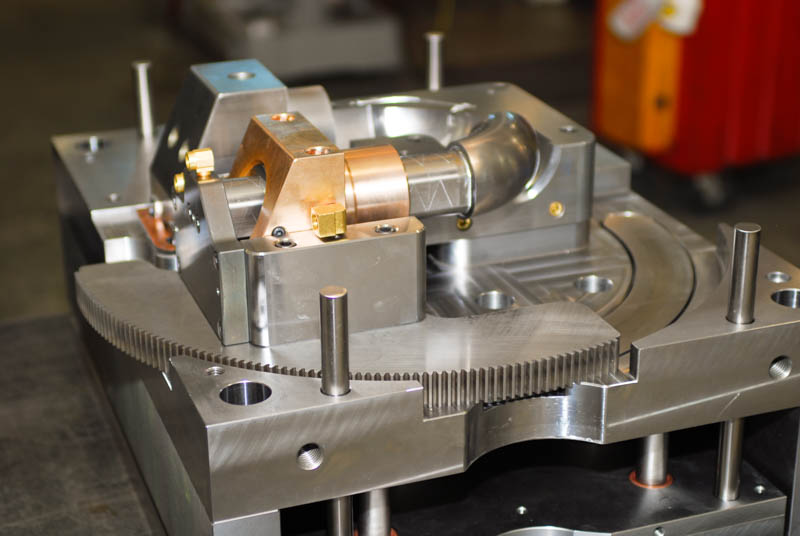

Sweep Elbow Molds

We have built a variety of interesting plastic injection molds for 90° sweep elbows. These molds feature automatic rotating cores, some of which are mounted slides. These complex molds attest to Superior Tooling's creativity, accuracy, and quality.

We have built a variety of interesting plastic injection molds for 90° sweep elbows. These molds feature automatic rotating cores, some of which are mounted slides. These complex molds attest to Superior Tooling's creativity, accuracy, and quality.

Move your cursor over the image to see another similar mold.

Robots In Production

We now have two fully automated robots performing both milling and EDM functions around the clock. The System 3R Workmaster robots are loaded and programmed by day to maintain machine productivity even when completely unattended. Our machine and facility video cameras can even be accessed remotely to monitor progress from home or client sites.

We now have two fully automated robots performing both milling and EDM functions around the clock. The System 3R Workmaster robots are loaded and programmed by day to maintain machine productivity even when completely unattended. Our machine and facility video cameras can even be accessed remotely to monitor progress from home or client sites.

New Machining Center

New EDM Sinker

Competing on a global scale in the new millenium requires a higher level of productivity. Our new Agie Charmilles FO 350 Sp is equipped with System 3R electode holders and pallets. Integrated with our Workmaster automatic robotic tool and part changer, this cell is made for ultra-precision operation 24 hours a day 7 days a week.

Competing on a global scale in the new millenium requires a higher level of productivity. Our new Agie Charmilles FO 350 Sp is equipped with System 3R electode holders and pallets. Integrated with our Workmaster automatic robotic tool and part changer, this cell is made for ultra-precision operation 24 hours a day 7 days a week.